Digitalisation wants to be “learnt”

Training with a Future: this is the slogan under which Siemens trains its apprentices – and has done since 1921. Particular emphasis is placed on the subject of digitalisation and Industry 4.0. It has also recently become possible to complete an apprenticeship and an undergraduate degree at the same time at one of Austria’s leading technology companies, so that there is now nothing to prevent anyone from making a successful start to a career with Siemens.

Since 1921, Siemens has trained around 6,500 technical/commercial and around 1,600 commercial trainees in their chosen apprenticeships. Today there are altogether around 400 apprentices, who are learning their trade from the ground up at the training workshops in Vienna, Graz, Weiz, Linz and Innsbruck. The training workshop in Weiz is particularly interesting, as in 2017 for the first time there were more young women than men starting a career in a technical trade at the Weiz transformer plant. Since 1977, this highly diverse corporate group has been striving to support young women in their choice of career and learning in what were once “male” trades – and this example shows that these efforts are bearing fruit.

Innovative approaches in the training of specialist staff

In September 2018, Siemens also launched an innovative educational opportunity for school students with its dual course of study. The apprenticeship in electrical and power engineering at Siemens in Vienna is combined with the “Smart Engineering” degree course at St. Pölten University of Applied Sciences. Upon successful completion, students are awarded not only an apprenticeship diploma but also a Bachelor of Science in Engineering. One of the first students enrolled in this programme is Simon Langhoff, who has been an apprentice at Siemens since 2017 and has been studying for his degree at the same time. What is a typical working day at Siemens like for Simon?

The alarm rings at 5.30 in the morning – except for Friday. “I always listen to quite loud music to wake myself up properly. Then I have breakfast and set off for work”, says Simon. The first thing he does after arriving at the office is to switch on the computer. “Because the job is so varied, there’s no such thing as a typical day in the office. However, I always start by checking my e-mails to get an idea of what the day holds. A coffee with colleagues or a meeting then leaves me feeling properly awake.”

What other things will he be doing? “If I’m not at the university, I’ll be looking after our suppliers or setting up seminars. In addition, customer relationships play an important part in my job and I deal with inquiries that come in on a day-to-day basis.” Simon manages to clear his head for a while at lunchtime, when he joins his colleagues in the staff canteen before returning to work for the afternoon. Fridays are spent at St. Pölten University of Applied Sciences, where Simon also faces a range of demanding tasks. As well as work and lectures, there are also projects to finish or exams to study for. “By way of balance, I enjoy going climbing or meeting friends in a bar or cafe,” adds Simon.

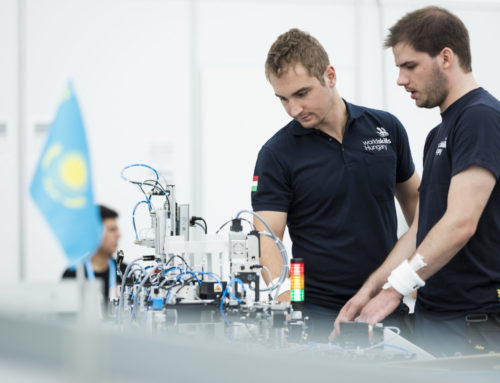

An apprenticeship at Siemens Austria focuses on the topic of digitalisation. Photo © Siemens.

Digital pioneers: focus on digitalisation in apprenticeships at Siemens

Alongside this special form of training, Siemens places particular emphasis on digitalisation, which is transforming many areas of life. That’s why the course content in the apprenticeship stage also needs to keep up with the changes in the economy. Siemens Austria is playing a pioneering role in this. The standard of training and education is well above the prescribed statutory level. Developing expertise in disruptive technologies such as cloud computing, machine-to-machine communication, additive manufacturing or robotics also requires new methods of teaching. The apprentices in the training workshops therefore have access to models of assembly lines, on which they can learn about sensor and actuator technology, networking and data transfer. Siemens Austria also provides the skilled workforce of tomorrow with 3D printers and intelligent industrial robots. “Learning islands” on the subject of Industry 4.0, which are provided in Upper Austria, are an additional highlight They represent a link between conventional education in the training workshop or vocational college, and practical application in the company, as the work done at these islands is very realistic. Up to four third and fourth-year apprentices work together on projects at the learning islands – over a period of up to six weeks, the teams work on the relevant project planning, look after the assembly and programming and then visualise the results.

Skills for a successful future

Sponsorship of EuroSkills 2020 therefore fits perfectly into the Siemens corporate strategy, as Gerhard Zummer, Head of Professional Education at Siemens Austria, confirms: “Our strong educational partnership with EuroSkills will increase the sustainable quality of vocational education in Europe. Our apprentices are constantly proving that they are fit for the future – and at EuroSkills, we work together to inspire young people to follow an apprenticeship.”

We would like to take this opportunity to thank Siemens once again for their commitment and we look forward to working with them – We are Skills!