Training 4.0 with Festo Didactic

Industry 4.0 is changing our entire working environment, especially with regard to manufacturing and production. The EuroSkills 2020 main sponsor Festo is one of the pioneers in this field and is therefore also ideally placed to offer relevant education and training.

Industry 4.0: The fourth industrial revolution

After the industrial mechanisation of the late 18th and early 19th century, the industrialisation later in the 19th century and the automation of the 20th century, our society is now in the midst of a fourth industrial revolution. This revolution is marked by digitalisation and integration, summarised under the heading of “Industry 4.0”. Broadly speaking, the “smart factory” – the factory of the future – will integrate and sustainably optimise the various industrial processes through the use of modern information and communication technologies. This will result in modern manufacturing processes becoming more productive, intelligent, controllable and transparent.

The key to success is digital transformation, which is creating the necessary technologies to meet the requirements of Industry 4.0 (higher production speeds and greater customisation), with conventional mechanical parts converging with components from information and communication technology to form cyber-physical systems. This in turn leads to the need for massive changes in the product development and production processes. Introducing and implementing Industry 4.0 is a continuous process in companies, involving not only challenges but also great potential for the automation industry; it also has a profound impact on the staff of those companies. The production process of the future has the following features:

- the entire production plant will be digitally integrated

- intelligent components with “plug-and-produce” functionalities

- the plant is virtually mapped for automatic start-up and reconfiguration

- rapid capacity balancing in a production network

- automatic adjustment of production lines to order volume

- ease of compensation for failed production units

- increasingly intelligent and adaptive production control

- customised, individual production

- constantly increasing human-machine interaction

Training is key to success

Even despite digital transformation, integration, automation and other developments, the human workforce still remains a key part of the modern production process. What is changing, however, are the tasks within a company. The role of humans within the industrial production process is changing from that of mere plant operators to problem solvers. There is close interaction between humans and machines, with each complementing the other, and training and education increasingly becoming key success factors. Service technicians, for instance, now need more than practical experience in mechatronics; they must also understand IT infrastructure so that they can restore a malfunctioning plant to operation rapidly and to the highest standard. New requirements will arise and will need to be met by appropriate training measures, with Festo being one of the pioneers in the field. “As pioneering innovators in factory automation, we know how important it is to prepare people for tomorrow’s challenges,” explains Rainer Ostermann, managing director of Festo Austria. “This calls for modern learning tools, the right concepts and training equipment that continuously adapts.”

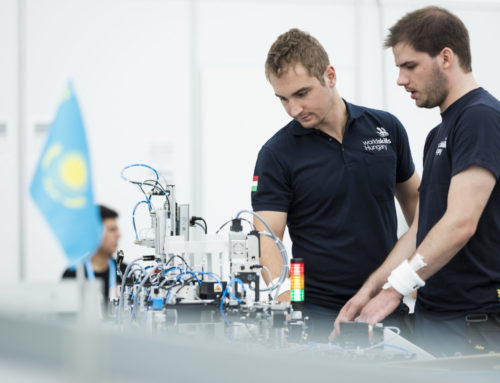

The company plays a leading role in the field of further education in technical skills and offers training courses, e-learning, and teaching and learning hardware – from standalone training units to highly integrated training factories. The learning platform CP Factory, for example, models a real production plant and so provides hands-on and interactive training in plant programming, integration, energy efficiency and data management. EuroSkills 2020 will also be using learning solutions from Festo Didactic, and WorldSkills, too, has also been supported by Festo for years. Rainer Ostermann explains Festo’s commitment: “When you enter the competition halls during the skills championships you immediately sense the enthusiasm and the commitment. These people are tomorrow’s experts, who are showcasing real, top-level performances. That’s why we have been supporting these contests in future-oriented skills and trades for many years now.”

Let’s hit the ground running – and shape the future with education and training!

Photos Gallery: Festo/Draper.

The “Future Skill” Industry 4.0 is strongly supported by our main sponsor Festo at EuroSkills 2020. Picture: Festo/Draper.